Why Media Fill Required in Aseptic Manufacturing? @PharMaven #pharma #media #aseptic #USFDA

Summary

TLDRIn this informative video, the presenter from PharmaWell YouTube channel delves into the critical role of media fills in the pharmaceutical industry. They explain the regulatory requirements outlined in 21 CFR Part 2, Subpart 1.113(b), emphasizing the need for written procedures to prevent microbial contamination during aseptic manufacturing. The video introduces the concept of aseptic process simulation, using soybean casein digest medium to mimic the production process without the actual product. This method ensures sterility and compliance with industry standards, providing viewers with a clear understanding of why media fills are essential for maintaining product quality and safety.

Takeaways

- 📚 The video discusses the necessity of media fill in the pharmaceutical industry, particularly for aseptic manufacturing processes.

- 📋 21 CFR Part 211, Subsection B emphasizes the need for written procedures to prevent microbial contamination, including validation of the sterilization process.

- 🔬 The guidance for industry from September 2004 also stresses the importance of validating sterilization processes involved in manufacturing.

- 🧪 Media fill is a method to ensure sterility by simulating the actual manufacturing process using a microbial growth medium instead of the product.

- 🌐 The components in the aseptic manufacturing process are sterilized separately and then assembled, which if not done properly, can lead to contamination.

- 📉 The use of soybean casein digest medium in media fill tests is highlighted, which supports a wide variety of microorganisms.

- 🔄 Media fill simulates the entire manufacturing process to closely mirror the actual conditions, including assembly, filling, and connections.

- 🔬 The purpose of media fill is to ensure that the sterility of the process is maintained and no microbial contamination is introduced.

- 📝 The video promises a follow-up video that will detail the steps of how to carry out a media fill.

- 👨🔬 The speaker concludes by emphasizing the importance of understanding media fill for ensuring product stability and sterility.

Q & A

What is the main topic discussed in the video?

-The main topic discussed in the video is the requirement of media fill in the context of the aseptic manufacturing process in the pharmaceutical industry.

Why is media fill necessary according to 21 CFR Part 2, Subpart 1.113 subsection b?

-According to 21 CFR Part 2, Subpart 1.113 subsection b, media fill is necessary to establish and validate written procedures designed to prevent microbial contamination of products.

What does the guidance for industry from September 2004 emphasize regarding the aseptic manufacturing process?

-The guidance for industry emphasizes the need to validate any aseptic manufacturing process that includes sterilization of components, filling, heating assembly, and the product contact path.

What is an aseptic process simulation?

-An aseptic process simulation is a method to ensure that components remain sterile by simulating the actual manufacturing process using a microbial growth medium instead of the actual product.

Why is it important to simulate the actual manufacturing process during media fill?

-Simulating the actual manufacturing process during media fill is important to ensure that the process is not resulting in microbial contamination and to validate the sterility of the process.

What is the purpose of using soybean casein digest medium in media fill?

-Soybean casein digest medium is used because it supports a wide variety of microorganisms, including proteins, carbohydrates, buffers, and sodium chloride to maintain osmotic balance.

What does the term 'aseptic process' mean in the context of pharmaceutical manufacturing?

-In pharmaceutical manufacturing, 'aseptic process' refers to a process that is conducted in a sterile environment to prevent contamination of the product by microorganisms.

What are the components typically sterilized separately in the aseptic manufacturing process?

-In the aseptic manufacturing process, components such as filling assembly, rubber stopper, wires, and product manufacturing tab filtration tank are typically sterilized separately.

What is the significance of the term 'grade B, A, B, C' mentioned in the script?

-The term 'grade B, A, B, C' refers to the environmental conditions required for different stages of the aseptic process, indicating the level of cleanliness or control necessary for each area.

How does media fill help in assuring the sterility of the final product?

-Media fill helps in assuring the sterility of the final product by simulating the actual manufacturing process and checking for any microbial contamination, thus validating the sterility of the process.

What will be the focus of the next video by the channel?

-The next video will focus on explaining the detailed steps on how to carry out media fill.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Understanding the Pharmaceutical industry | Starweaver

Le conseguenze della crisi del '29 in Europa [Dentro alla storia, episodio 253]

O Lado OBSCURO da Indústria Farmacêutica..

Fundamentals of Stock Analysis | A step-by-step process to analyse stocks #StockMarket

PEDAGANG BESAR FARMASI (PBF)||BISNIS FARMASI TIDAK HANYA APOTEK LHOO!! #APOTEKER #DISTRIBUTOR #APJ

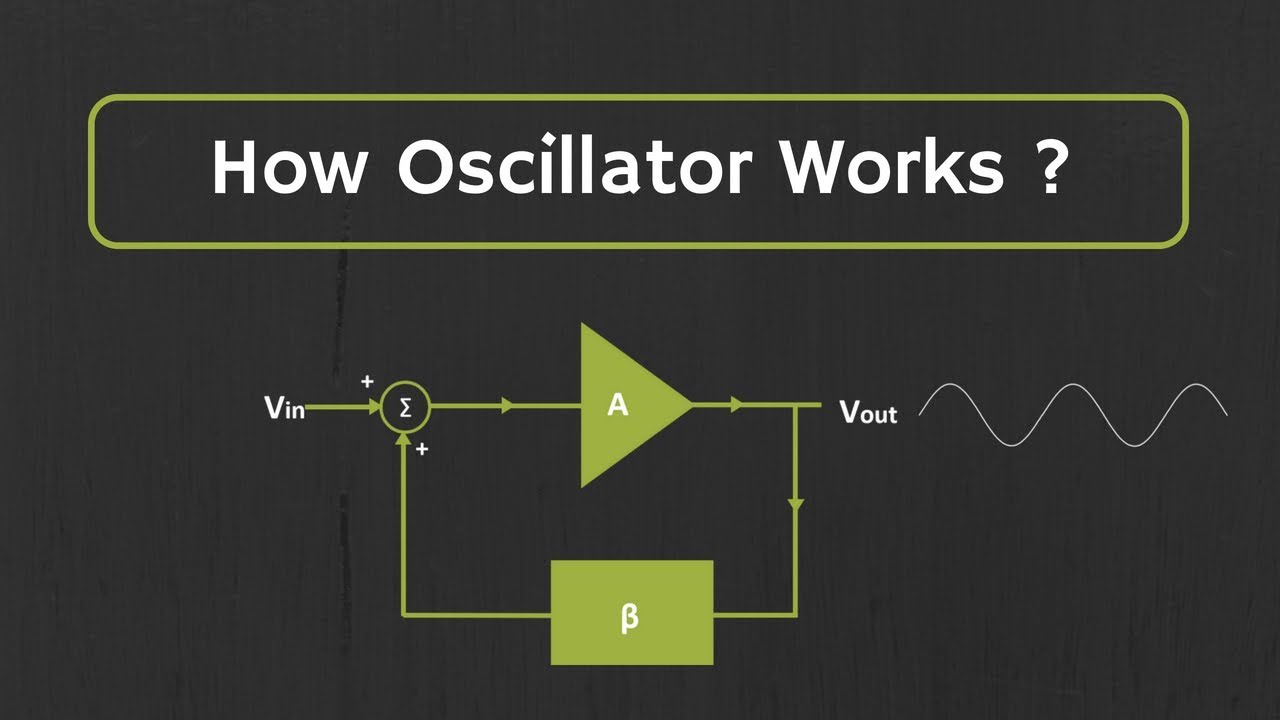

How Oscillator Works ? The Working Principle of the Oscillator Explained

5.0 / 5 (0 votes)